-40%

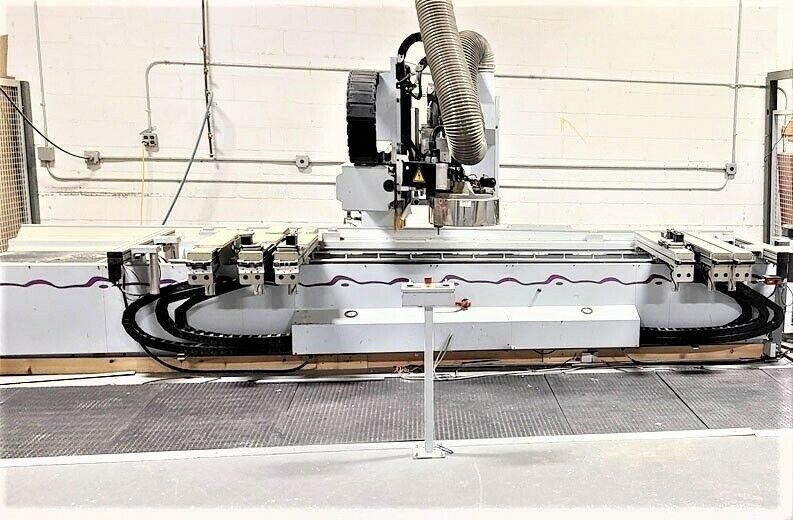

WEEKE VANTECH PROFILINE BHP 007/510 3-AXIS CNC ROUTER NEW 2011

$ 31416

- Description

- Size Guide

Description

WEEKE VANTECH PROFILINE BHP 007/510 3-AXIS CNC ROUTER NEW 2011HSK 63 Router Spindle Power (constant from 9000 rom to 18000 rom) 9.0 kW/12.0 HP

Router Soindle Sneed 1,250 - 24,000 rom

Tool Ma11azine Capacity 8

Pneumatic Reference Pins 3

Vacuum Pomo Caoacitv 4 Pornos w/ total capacity 432 m3/h

Workin2 LeDllth 2438mm/8'

Wor.kiDI!: Width U19mm/4'

Maximum Workoiece Thickness 100mm

Axis Stroke/Positionio2 Soeeds

X-Axis 3938 mm11s5"n2 mtmin

Y-Axis 1952 mm/77"/62 m/min

Z-Axis 245 mm/9.6"/25 m/min

X/Y Vector Sneed 96m/min

Installed Machine Weil!ht 7,495 lbs.

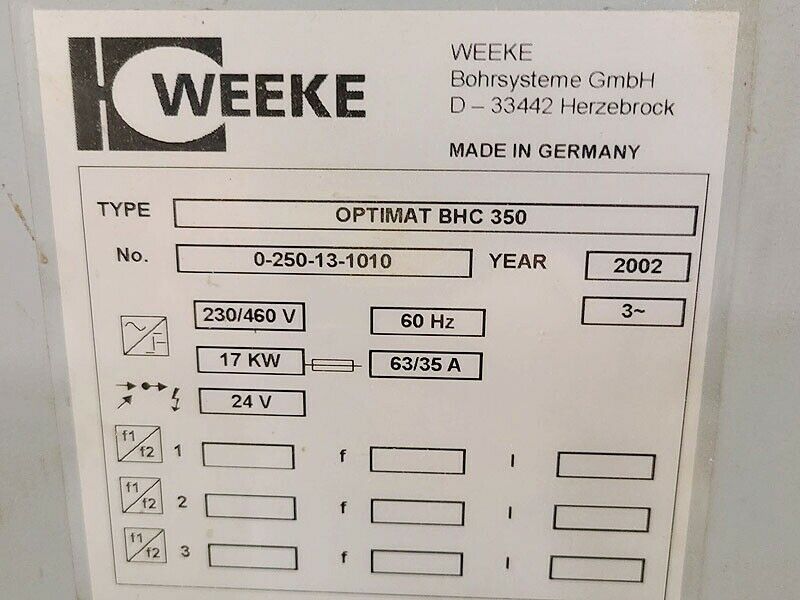

Utility Requirements

Electrical

Ooeratin11 Voltal!e 480 Volts/ 3 Phase/ 60 Hz

AmperBfie Service 50 Amn.11 @ 480 Volts

Control Voltae.e 24 Volt

Total Connected Load 27.SkW

Dust Extraction

Connection Size(s) 200 mm (7 7/8")

Hei2ht - aoorox, 2230 mm (87 3/4")

Air Velocitv (minimum) 28 m/sec - 92 ft/sec

Static Pressure Minimum 2200 Pascal

Air Volume 3170 m:1/h - 1900 cfm

Compressed Air

Connection Size(s) R½inch

Pressure Reouired 100 osi - 7 bar

Consumption Volume 100/2001/min-10-15cfm

Ambient Temoerature

Ooerating Range 35° C (max) - 95° F (max)

Foundation Reouirement

Concrete Thickness 200 mm (min.) - 8 inch (min.)

7-Splndle Vertical Drill Block

A vertical drilling block with seven (7) spindles is included.

Special feature: Spindle clamping to achieve the drilling depth safely. Stroke Z-direction: 60 mm

Drilling depth: maximum 38 mm (up to 55 mm for special borers) Direction of rotation: right hand/left hand

Speed: 3,450 rpm Power: 1.5 kW

Shaft diameter: d = 10 mm Total length of drill: 70 mm

Drilling diameter: maximum 35 mm Distance between spindles: 32 mm Type of spindle: individually selectable

MATRIX Tables· x 10'

WEEKE VANTECH 510 PAGE 4

System MATRIX phenolic vacuum table with grid grooves for fixturing of work pieces. The grooves provide for efficient distribution of vacuum, as well as isolating table areas by inlaying a rubber sealing and/or accepting vacuum pods for fixturing small parts.

The MATRIX system offers:

• Vacuum system for clamping of the work pieces on the surface of the vacuum table

• The working table is divided into 4 vacuum zones

• Can be equipped with the Quick Pod System for machining small parts

• Working table length: 3100 mm (10' / 122 Inches)

• Working table width: 1550 mm (5' / 61 Inches)

• Workpiece thickness: maximum 100 mm (3.94 Inches)

o Includes 65 feet rubber gasket material

Vacuum System:

• The machine design includes four vacuum pumps with a total vacuum capacity of 432 m3/h, 60 Hz (4 x 108 m3/h, 60 Hz). They are directly connected with the vacuum table via a distribution device and one of the three vacuum generators serves as master.

• The vacuum system is one of the largest electrical consumers of the machine. For this reason, the Vantech system utilizes an Eco-Friendly design to conserve energy and save money. The pumps operate from a "staggered start" to reduce the maximum draw of the machine upon start up and single pumps can be switched off to save energy when not required.

• Vacuum zones are activated via soft key at the control panel, outperforming common manual vacuum valve systems.

• The vacuum pumps are mounted within the machine foundation, positioned neatly below the machine table saving floor space and promoting safety.

Note: f,xture board material (also referred to as "bleeder board" or "spoil board") is not supplied with the machine, but required at time of installation.

German Engineering - Manufactured in the USA 1111§

stiles

SHOP

SOLUTIONS

_i_lilass !!opcom

Vertical Router Spindle

WEEKE VANTECH 510 PAGE 5

• HSK63 9.0 kW (12HP) spindle motor that includes an automatic tool change feature in combination with the tool change magazine.

• Direction of rotation: right hand / left hand

• Speed: 1,250 - 24,000 rpm stepless programmable

• Drive: frequency controlled AC-motor

• Maximum capacity at the tool: up to 7.5/9 kW (10/12 HP) in continuous and intermittent operation (S1/S6 - 50%)

• Spindle lubrication: permanent grease lubrication

• Bearing: hybrid bearing (ceramic), little friction, higher stiffness and maximum operating life

• Air cooled

• Central dust extraction

Air Jet

Four air jets are integrated into the extraction hood providing a cool, clean and efficient machining area. Air jets are activated via soft key at the control panel.

Automatic Tool Change

To increase flexibility and decrease cycle time, an automatic tool changer (ATC) is arranged near the left of the machine framework.

Features:

• Tool holder: HSK63

• Magazine places: 8 tool places

• Tool weight: maximum 5 kg

including OSK cone

• Tool diameter: 135 mm max when equipped with 8 tools

• Tool change time: approximately 10 - 18 seconds

• Tool loading: via integrated pick-up

place at the tool changer Automatic Tool Changer

Tool Length Control

Tool Touch Off

A heavy duty tool length control system is a standard feature of the machine. To maintain accuracy, tooling is touched off after a change via the tool pick up station and its length is verified against the tool data stored within the machine control.

German Engineering - Manufactured in the USA 11111§

stiles

SHOP

SOLUTIONS

Reference Pins

WEEKE VANTECH 510 PAGE 6

2

Reference Pin Locations

WoodWop

3-D CNC Simulation

There are there three (3) pneumatically actuated aluminum workpiece stops mounted at the machine table. Two are located at the rear of the machine and one is located at the left of the machine for accurate material positioning. Pins are automatically controlled by the machine.

Vantech Maintenance Kit

A tool kit is included with the machine consisting of: 46mm single open end wrench, 58x62mm hook spanner wrench; grease gun with hose, grease and ball end alien wrench set.

Power Control PC85T

The Vantech 51O features a Microsoft Windows based control complete with intuitive software. The included WoodWop programming system is the heart of the machine and is unmatched by any programming software available today. The powerful drawing functions offered by WoodWop simplify programming for operators without CNC experience and provide the premium features required to satisfy advanced users. In addition to the software within the machine control, a copy of the program is included for installation on an office PC for off-line programming.

Hardware:

• Off the shelf 17" flat screen monitor, keyboard and an industrial PC

• Operating system Windows XP (US) embedded

• PLC control according to international standard IEC 61131

• USB connection at the operating panel

• EtherNet connection 10/100 MBIT RJ45 (without switch)

Machine Software Bundle: (software pre-loaded on the machine PC)

PC8ST software package with graphical operating programs:

• WoodWOP for powerful, yet simple generation of CNC-programs o Graphical tool selection from your database

o Production list administration

o Graphical presentation of work zones

o Oear text error messaging

• Schuler MDE Basic for machine data recording

• 3D NC-Simulation and Time Calculation: One (1) license

PC85T CNC-Core Includes:

• Path control in all axis and parallel sequences by multi-channel technology

• Look-ahead-function for optimal speed at the transitions

Gerrnan Enoineering - Manufactured in the US/-\

stiles

SHOP

SOLUTIONS

Ii

Wood Nest Basic

WEEKE VANTECH 510 PAGE 7

Software for External PC - Single Seat Licenses for the Following Programs:

Requires computer operating Windows NT4, 2000, XP, Vista or 7

• WoodWOP for powerful, yet simple generation of CNC-programs

• DXF-postprocessor Basic for the data exchange from 2D-CAD-programs to

WoodWOP

o Import of 2D-DXF-files via pre-determined layering rules

o Display ofgeometry, layer and drawing elemen ts

o Generation ofWoodWOP program files

• WoodNest Basic

o Software for the Nesting ofWoodWOP program files

o Manual positioning and turning ofwork pieces by drag and drop

o Visualization ofspacing between work pieces

• WoodWOP MOSAIC

o Software to view thumbnails ofWoodWop files

o Allows WoodWOP data files and complete directories to be managed from a graphical point ofview

o Programs can be administered by drag and drop

• WoodType

o Software to generate routing contours for characters and texts in all available Windows True Type fonts

Manuals and Control Texts

• Standard Manuals, CD, as well as .PDF versions stored on the machine containing operating and maintenance instructions

• Display texts for machine operators of the POWER CONTROL

• Spare parts descriptions consisting of CAD-drawings and wiring diagrams

German Engineering - Manufactured in the USA �

stiles

SHOP

SOLUTIONS

Technical Specifications

WEEKE VANTECH 510 PAGE 8

Stock Number

12687

WEEKE VANTECH 510 PROFILINE BHP 007/510 CNC ROUTER

Video will open in a new window

Using the eBay App? Paste link into a browser window:

[isdntekvideo]