-40%

3KW Wood CNC Router Engraving Drilling Machine Water Cooling DSP 8ft*4ft 1325

$ 2692.8

- Description

- Size Guide

Description

3KW Wood CNC Router Engraving Drilling Machine Water Cooling DSP 8ft*4ft 1325Product Description

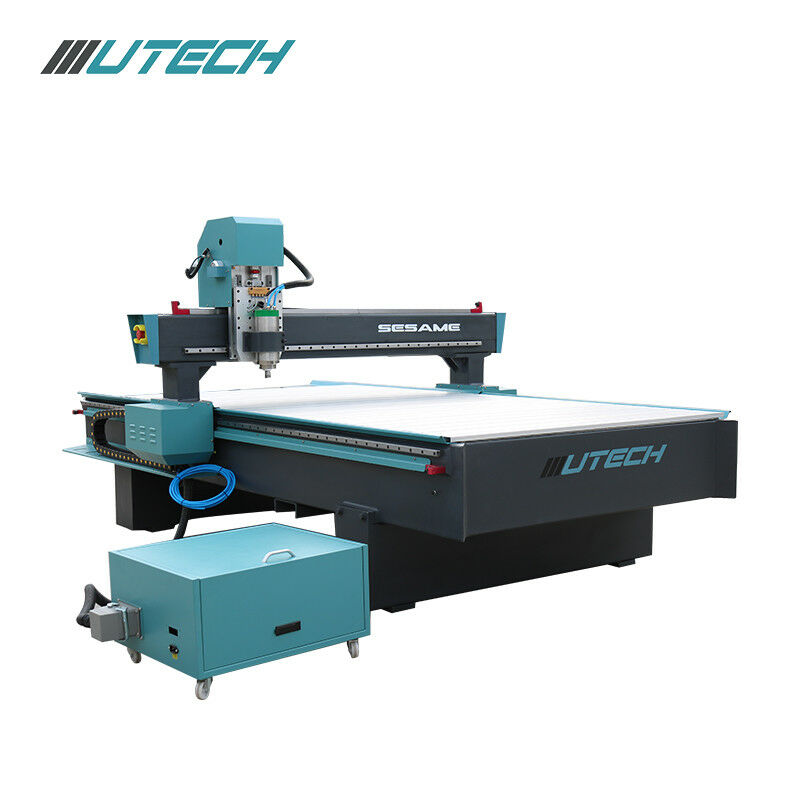

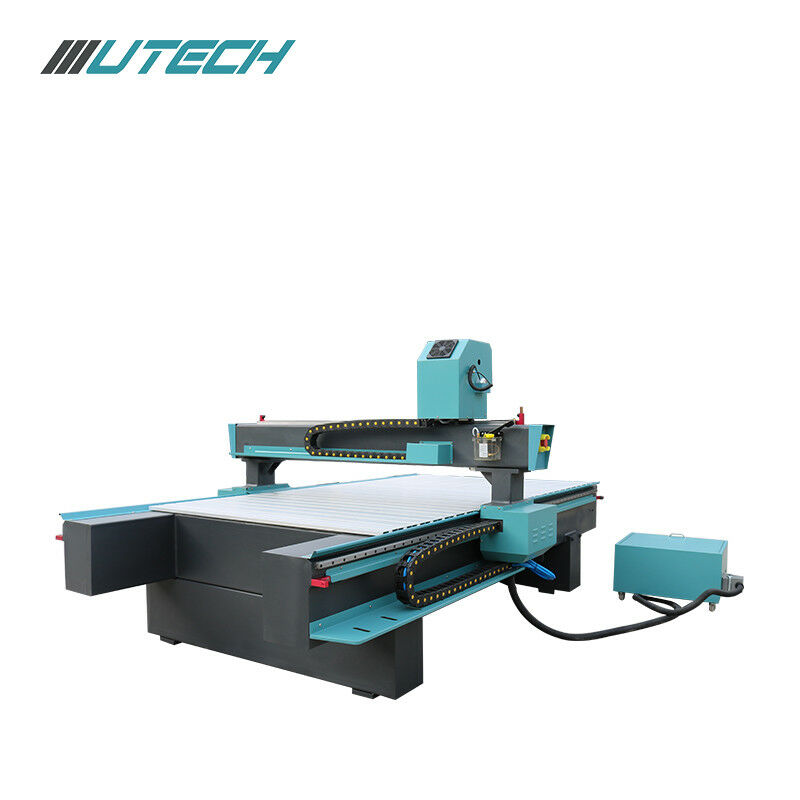

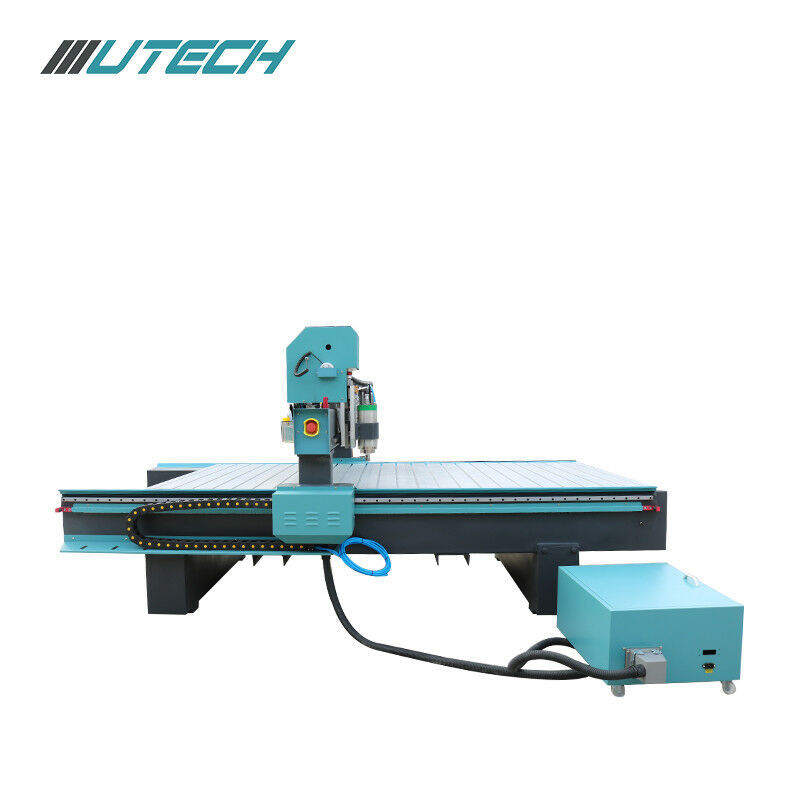

Machine photos:

Technical parameters:

Model

Sesame-1325 3 axis cnc wood router machine

Working Area

1300*2500*200mm

Spindle Power

3.0kw water cooling spindle(option:Italy HSD air cooling spindle)

Table

Vacuum table(option:T-slot table)

X,Y,Z axis Transmission Way

X Y axis rack transmission,Z axis TaiwanTBI Ball Screw transmission

Guide Rail

Import HIWIN Square Guide Rail

Spindle Speed

0-24000RPM

Drive Motors

Leadshine stepper motor and driver(option:servo motor and driver)

Inverter

Delta(option:Fuling)

Working Voltage

AC380V/3PH/50Hz(option:220V/50hz,single phase)

Command Language

G Code

Operating System

Richauto-A11 DSP control system(option:NC-studio)

Software Compatibility

Option:Type3, Ucancam, solidworks,etc.

Certificate

CE FDA

optional

Auto tool changer

Dust collector

Detailed Images

Main Configurations:

#.3.0KW water cooling spindle

wood cnc router eastern for sale/cnc wood router/cnc router

#.Heavy duty body (After Quenching process, no deformation, 8-10 bed, very stable )

#.Cast gearbox (stronger stability, high precision, and long life )

woodworking machine

#.Xinyue helical rack ( Low noise and high precision )

#.Omron electric ( Low tension )

wood carving machine cnc

#.Fuling inverter ( High efficiency )

#.X Y axis gear transmission

#.Z axis Taiwan TBI ball screw transmission

#.Taiwan Hiwin G20 rails+Flange

w

oodworking machine/wood cnc router eastern for sc router

#.RichAuto A11 DSP system

#.Leadshine stepper motor

wood carving machine cnc

#.Leadshine M860 driver

#.Filter

#.Tool sensor

Detailed Images

1. The bed

is the backbone of a cnc router machine, our machine bed adapts 200*300mm thick wall steel square tube welded together, solid and not deformed. After high-temperature tempering treatment to ensure the best strength and rigidity side arranged structure, heavy column,150*150mm gantry. Compared to ordinary machines, it has better stability.

2.The forklift location display

of Sesame CNC router machine.

Forklift loading and unloading reserved space, which can better protect body and cargo carrying weight.

3. According to overseas custom demand and market research, as for the overall design structure of the bed body, we adopt separated type lathe bed structure. For the purpose of After ensuring that the customer receives the equipment there's no need to make a complete disassembly and will not affect the operation of the equipment. In this circumstance, we optimized the design structure, then, the final packaging size of the product was saved by 5 cubic meters . Thus saving transportation costs.

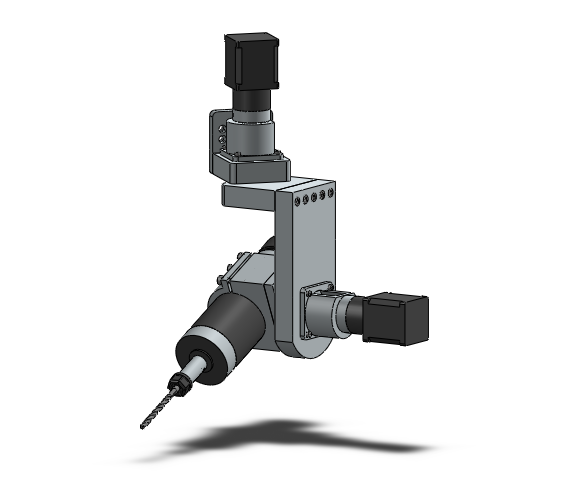

4. The machine head

of Sasame is made of T6061/6030 aluminum parts by professional CNC machining center. After the oxidation surface and low temperature annealing treatment, the machine head is lighter and more durable.

5. Because the accuracy of cnc router machine is greatly depends on the

spindle

, The Sesame series CNC Router machine comes with 3.2kw water cooling spindle or 3.5kw high frequency Air cooling spindle. Thereby the high precision spindle can considerably reduce maintenance. Fully programmable speeds from 6000 to 24000 RPM, It have more efficiently than before. and comes complete with pneumatically retractable vacuum hood.

6. Sasame use GC

HIWIN 20mm square linear rails

add Flange slider. The Y-axis adopts double-row four-column guide rail, with strong bearing force, fast speed, smooth operation, high precision and high life span.

Rack of Sesame adopts a high-precision 1.25 helical tooth rack, which is complementary with the professional motor and professional deceleration device, which runs smoothly, high speed, high precision and low noise.

7. Sasame use Stepper motor, the machine torque is big, processing speed is quick, the highest speed can reach 40m/min. With reducer transmission, the machine is more stable, high efficiency, high precision and low noise.

Patent design 1:4 gear reducer

install on the driving motor, makes the motor is more powerful, and having a longer time service life.

The stepper motors

are installed on all axes to ensure precise positioning of the gantry and the spindle in accordance with a predetermined program at high speed. Stepper motors are well proven high degree of reliability.

The machine is installed 4 pieces of motors and patent type stepper reducer*3

8.Sesame adapt Portable detached optional design

control cabinet

Company Information

Our factory:

Shandong U-MAY CNC Technology CO., LTD.

Specializes in the research, development, production of CNC MACHINE. Our brand “WIN” has a considerable reputation in the domestic similar products, which has been widely used in wooden furniture, advertising, craft gifts, packaging and printing, logo and etc. Our products have been exported to many countries and regions such as Europe, Russia, Asia, Africa. We are committed to the enterprise management philosophy “Integrity-based, constant innovation, effective communication, quality services” and the goal of “Technical service customer”, but also great attention to product design, manufacture, installation, adjustment. We will still try our best to maintain a one-stop professional service.

Applicable Industry

Application of Wood CNC Router

1.Cabinets & Furniture

Custom and general cabinet manufacturing are one of the most popular applications for CNC routers. BCAM CNC routers have brought industry standards to a new level with our quality and components, delivering what you would find in much higher-priced CNC routers for a cost competitive with less industrial designs.

Our routers give cabinet makers the ability to manufacture many different styles of cabinet sets, closet sets, doors, drawers, shelves, and countertops with ease and precision. These machines also allow shops to expand their capabilities to include intricate furniture designs such as chairs, tables, rail systems, and much more. With 2D, 3D, and even 4th axis capabilities, our machines let you drill quicker, cut more accurately, and get a completely smooth finish without ever having to hand sand. BCAM CNC machines are only limited by the imagination. Cut costs and increase profitability in your cabinet and furniture production with a NEW BCAM CNC router.

2.Sign making & Carving

BCAM CNC routers are found in the everyday hobby shop all the way to full-production manufacturers in the sign and carving industries. Whether you are working with foam, wood, plastic, acrylic, aluminum, brass, or a variety of other materials, we have a BCAM CNC router that fits your sign making and carving needs. With a wide range of options including vision recognition systems, ADA signage capabilities, tangential knife systems, or multiple tool capabilities, there is an option for any level sign shop.

Our CNC routers bring the ability to design a very simple 2D project or a much more complex 3D sign or carving. With the BCAM CNC router, you can use existing .DXF files, clip art, and photographs, or you can create your own design from scratch with our simple but powerful controls. Whether you are looking for a “rustic” look or full-production finish, BCAM has the capabilities to deliver the result you want. Our systems have raised the bar on the average CNC router by giving shops and manufacturers the ability to produce better signs and carvings for less.

3. Musical Instruments

Creating a musical instrument takes flawless precision and accuracy. BCAM CNC routers are built with high-quality components to deliver the reliability and value that musical instrument manufacturers can’t find elsewhere.

BCAM has brought the ability of mass production and custom one-off fabrication to many musical instrument manufacturers, allowing them to tailor their products to the customer. Don’t limit yourself to generic instruments because of average equipment. Become a maestro at musical instrument manufacturing with the unparalleled technology of a BCAM CNC Router.

4. Plastics & Foam

To get precision and accuracy when cutting plastic or foam, you need a machine that doesn’t compromise on quality. BCAM CNC routers help many manufacturing facilities produce better plastic and foam products. Our routers are equipped with an upgraded frame, gantry, and drive system technology to handle a wide range of plastics and foams so you get flawless results every time.

Whether you are working with sheets in a high production setting or one-off parts in a more labor-intensive product, a BCAM CNC router has the solution to help increase production while maintaining a favorable budget. Don’t outsource your materials when a BCAM CNC Router can bring your work in-house and put the dollars back in your pocket!

5. Prototyping & 3D Modeling

Prototyping and 3D modeling are often essential parts of the production process. You need your prototypes and 3D models to come out perfect so you can see the true possibilities of your concept. BCAM CNC routers have all the capabilities you need to create the prototypes and 3D models that will become the next breakthrough product.

BCAM CNC routers are found in some of the most prestigious prototyping and 3D modeling facilities in the world. Some of the everyday products we use today were developed and prototyped on BCAM machines. Our systems allow you to scan, copy, engineer, and reverse engineer components so you can create the most innovative products. The added precision, dependability, and low operating costs of a BCAM router allow you to prototype and 3D model even the most advanced products.

6. Metal Fabrication & Steel Applications

When you’re working with metal, you need a cutting solution that will deliver power, precision, and a perfect finish. Our CNC plasma systems provide all the capabilities you need for any metal project including pipe, tube, corrugated metals, expanded metal, or flat sheet stock.

Whether you are a custom street or hot rod shop, race shop, or industrial equipment manufacturer, we have a CNC plasma system to fit your application and budget. Our machines are equipped with the necessary components and software to give you the ability to create some of the most extreme signs and yard art, HVAC, brackets, and other various metal fabricated products. Our unique software will help you finish this work.

Packaging & Shipping

1. Film. Put PE film on the machine and some spare parts, then put bubble wrap to the machine.

2. Free-fumigation wooden case with steel tube support on wooden cover. The humidity-proof paper above the wooden plate. This kind of package could protect the machine very well from dust and humidity etc.

FAQ

FAQ:

How to choose a good machine?

1)Machine quality. If you plan to choose a so cheap machine, maybe the quality is bad. And you have to order another

machine after you use it for a period. This situation will have a bad effect on your producing. So the quality of the machine is the most important factors to choose a machine.

2)Future more, aftersales service is very important, too. Good aftersales service represent the image of a company.

After you use the machine and find some problem with the machine, a good after

sales can solve it effectively and protect

the rights of consumers.

3)The third is technical support. Because of the time difference, there is a big problem to communicate with the seller. When you need help, maybe it is the sleeping time for the sellers. So the effective contact information and services are also useful to you

. Other sellers maybe can not do this, but our company can provide 24th service a day,we could go

to your place to help you solve some problems if necessary.

4)The last is company. In order to ensure their image, a company was ith good reputation usually can prod the use good

quality machi ne.As our company, we specialized in CNC machine than 10 years,

the professional

engineer

teams,the advanced equipment and the good service have earned us the good reputation in the world market.